Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) leverages its foundational expertise in high-precision bearing R&D and manufacturing to deliver superior Custom Flange Solutions.

Product Introduction: Engineered Precision for Critical Connections

FTM’s Custom Flanges are not merely connection components; they are high-precision parts meticulously engineered to integrate seamlessly into your most demanding applications. Designed for maximum performance, our flanges are specifically tailored to meet unique application requirements, offering a perfect fit where standard components fall short.

We provide comprehensive customization across critical parameters:

- Dimensional Specifications: Precise tailoring of Outer Diameter (OD), Inner Diameter (ID), bolt hole patterns, and flange thickness.

- Material Selection: Offering a variety of materials including Carbon Steel, Stainless Steel (e.g., SS304, SS316 for corrosion resistance), Alloy Steels, and non-ferrous options, selected based on the operating environment (temperature, pressure, and media).

- Shape and Configuration: Production of various types, such as Weld Neck, Slip-On, Blind, Socket Weld, Lap Joint, and Orifice flanges, customized to the specific connection type.

- Surface Finish and Machining: Utilizing advanced CNC technology to achieve superior flatness and surface finishes required for tight sealing, especially crucial for high-pressure or vacuum systems.

Technical Applications and Industry Relevance

FTM’s custom flanges deliver high precision and exceptional durability, establishing reliable connections between pipes, pumps, valves, and structural components in mission-critical industries:

- Oil and Gas (Upstream and Downstream): Used in pipelines and wellhead equipment where sealing integrity under high pressure and temperature (HPHT) is paramount to prevent leaks and ensure safety.

- Chemical and Petrochemical Processing: Utilizing corrosion-resistant materials (e.g., Duplex/Super Duplex steel) to handle aggressive and volatile chemical media.

- Aerospace and Defense: Requiring lightweight, high-strength materials and stringent dimensional tolerances for specialized fluid control systems.

- Heavy Machinery and Engineering: Providing robust connections in large-scale equipment where vibration resistance and structural strength are essential.

Manufacturer Advantage: FTM’s Edge in Precision and Reliability

Our ability to produce high-quality custom flanges is directly underpinned by our core competency in high-precision bearing technology:

- 30+ Years of Precision Machining Heritage: Our entire production process benefits from the same rigorous quality control and ultra-precise machining techniques (e.g., sub-micron level tolerances) historically applied to our high-accuracy bearings. This ensures superior flatness and perpendicularity, which are vital for leak-proof flange connections.

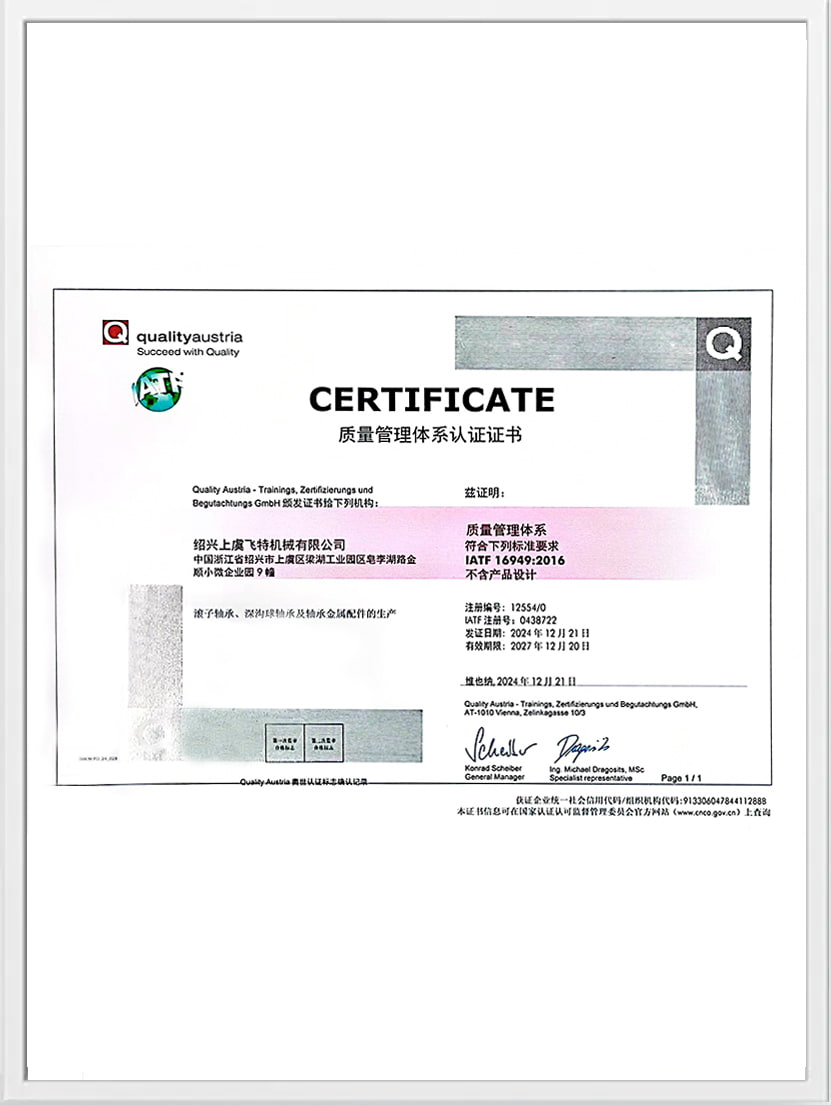

- Professional Technical Design Team: FTM employs experienced engineers who work closely with clients to move beyond basic dimensions, optimizing material stress calculations and ensuring compliance with international standards (e.g., ASME, API, DIN). We offer expert advice on pressure ratings and sealing surface design.

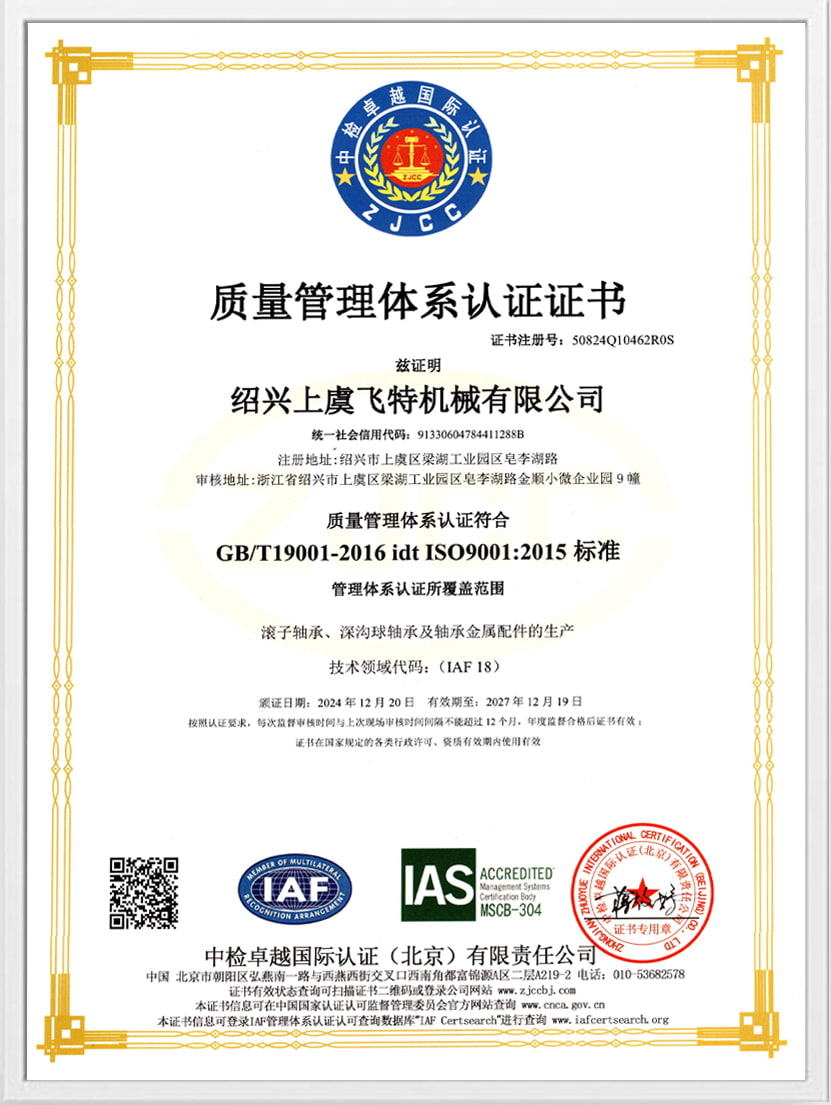

- Comprehensive Quality Assurance (QA): We employ advanced testing protocols, including Ultrasonic Testing (UT), Magnetic Particle Inspection (MPI), and precise dimensional metrology, guaranteeing product reliability and long-term performance under extreme operating conditions.

- Import Substitution Capability: Our focus on high-quality manufacturing positions FTM as a reliable domestic and international supplier capable of producing complex, high-specification flanges that meet or exceed the performance of imported equivalents.

Frequently Asked Questions (FAQ)

- What types of design files does FTM require for a custom order

- FTM typically requires 2D drawings (PDF DWG) and 3D models (STEP IGES) detailing dimensions tolerances material specifications and pressure ratings.

- What is the typical lead time for a custom flange order

- Lead time is determined by the material complexity the volume and any special testing requirements. We will provide a specific timeline after design confirmation.

- Does FTM assist with material selection for specific operating environments

- Yes our technical team offers consultation to recommend the optimal material alloy and surface treatment based on the intended application temperature pressure and media compatibility.

- What are the standard pressure ratings FTM can manufacture to

- FTM can produce custom flanges adhering to common pressure class standards such as Class 150 Class 300 up to Class 2500 and higher based on client specifications and required wall thickness calculations.

- How does FTM ensure the sealing integrity of its flanges

- We guarantee sealing integrity through precise surface finish control on the gasket contact area ensuring specified roughness and flatness as well as rigorous dimensional testing on the bolt holes and diameter to prevent stress concentration during installation.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog