A shaft is a critical component in any mechanical system, typically a cylindrical structure that transmits power, facilitates rotation, or supports other components. Usually mounted in bearings, shafts can be fixed or rotating, providing support for essential elements like gears, pulleys, and couplings.

FTM: Over Three Decades of Expertise in High-Quality Custom Shaft Manufacturing

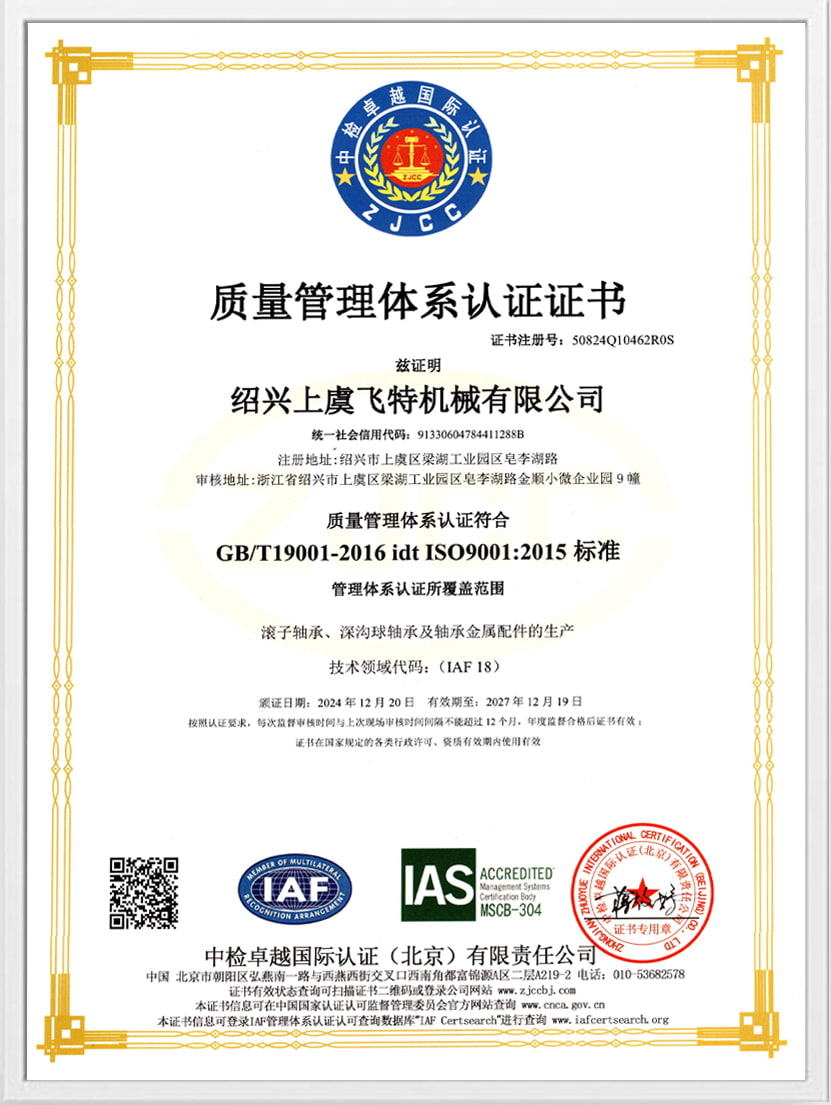

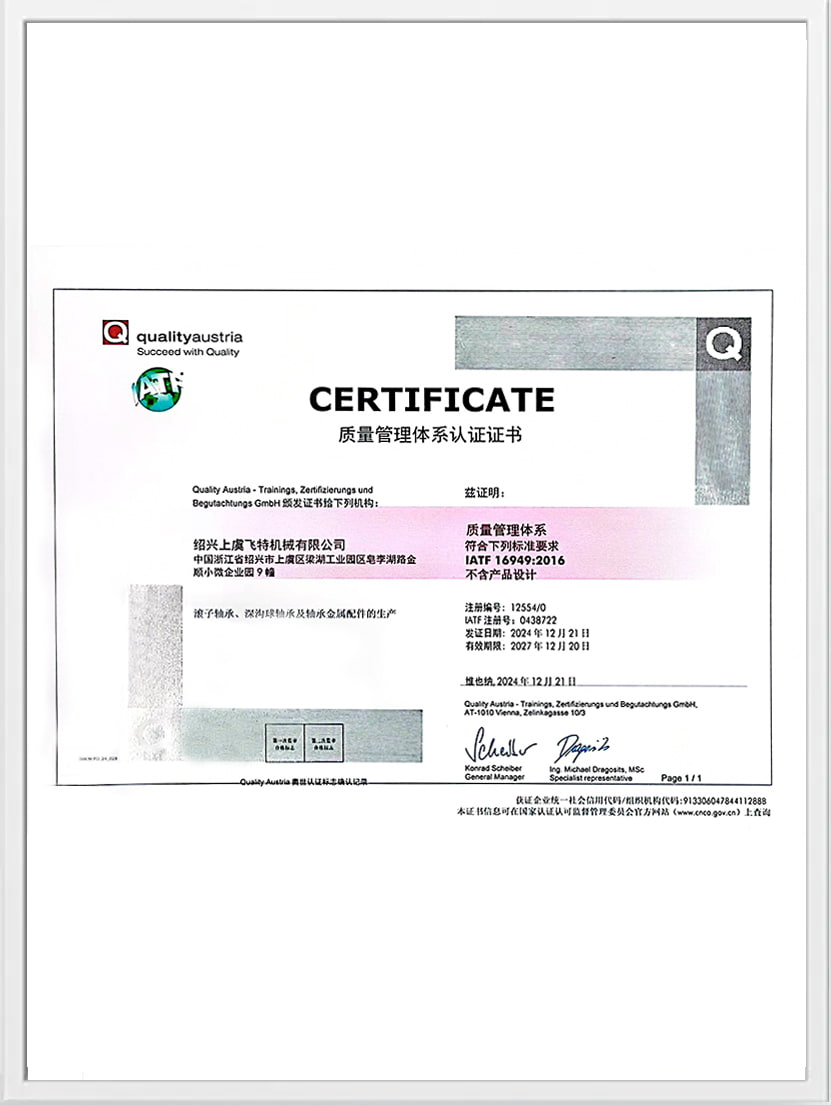

With over 30 years of technical design experience in the bearing field, Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) specializes in the R&D, manufacturing, and customization of non-standard bearings, high-precision bearings (import substitution), and bearing accessories and mechanical parts. Understanding the pivotal role shafts play in diverse machinery, our dedicated team and advanced processes are committed to delivering outstanding custom shaft solutions for our clients.

Meeting Diverse Needs: The Broad Applications of FTM Custom Shafts

FTM excels in the precision machining of shafts, producing customized solutions based on specific customer requirements and application scenarios. Our custom shafts are widely used in construction machinery, textile machinery, and other fields. Common types include:

-

Drive Shafts: Used to transmit power from one component to another, such as the drive shaft in a car that transfers power from the engine to the wheels.

-

Rotating Shafts: Designed to support rotating components, commonly found in motors, generators, and other machinery.

-

Main Shafts: The primary rotating shaft in a mechanical system, like the spindle in a machine tool that secures and rotates cutting tools or workpieces.

-

Crankshafts: Frequently used in internal combustion engines to convert the linear motion of pistons into rotational motion.

-

Linear Shafts: Utilized to support linear movement, often found in automation equipment and robotic arms.

FTM Custom Shafts: Superior Craftsmanship and Material Selection

FTM offers custom shafts in various shapes and with diverse processing capabilities:

-

Processing Size: We can machine shafts with diameters ranging from 10mm to 250mm.

-

Surface Treatment: We provide various surface treatment options, including zinc plating, black zinc plating, and electrophoresis, to enhance corrosion resistance and aesthetic appeal.

-

Processing Techniques: Our advanced processing techniques include drilling, threading, and grooving, ensuring the functionality and precision of each shaft.

-

Material Options: We offer a selection of high-quality materials such as stainless steel, bearing steel, carbon steel, and alloy steel, to meet specific requirements for strength, hardness, and wear resistance across different applications.

The Core Advantages of FTM: Precision Manufacturing and Dedicated Service

By choosing FTM, you gain:

-

Experienced Professional Team: With over 30 years of industry experience, our team deeply understands client needs and provides expert engineering design and technical support.

-

High-Precision Manufacturing Capabilities: Through advanced processing equipment and stringent quality control, we ensure every custom shaft meets high-precision and quality standards.

-

Exceptional Customization Service: We work closely with you from design to production, offering expert advice every step of the way to ensure the final product perfectly aligns with your specific application.

-

Reliable Solutions: Whether it's complex non-standard shafts or high-precision replacement shafts, FTM delivers stable and reliable solutions that help your mechanical systems achieve outstanding performance.

We look forward to collaborating with you to custom-craft high-quality shaft products that precisely meet your unique requirements.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog