About FTM: Your Partner in High-Precision Bearing Solutions

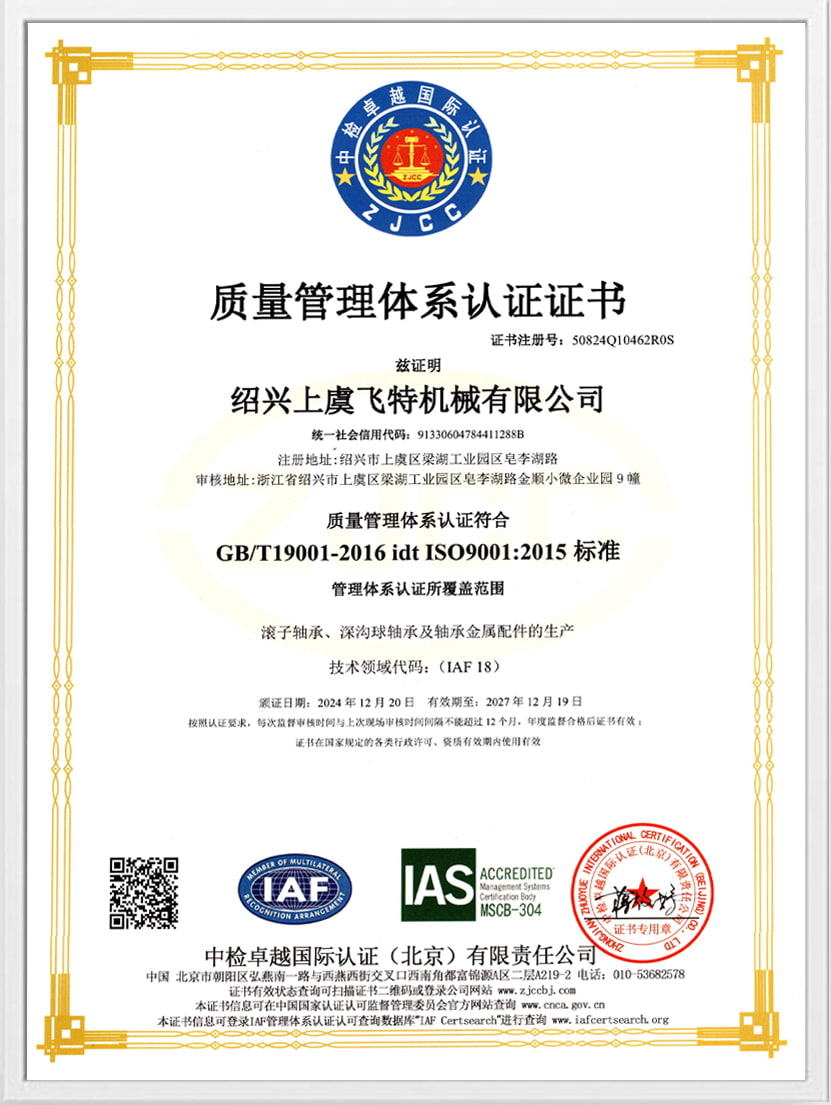

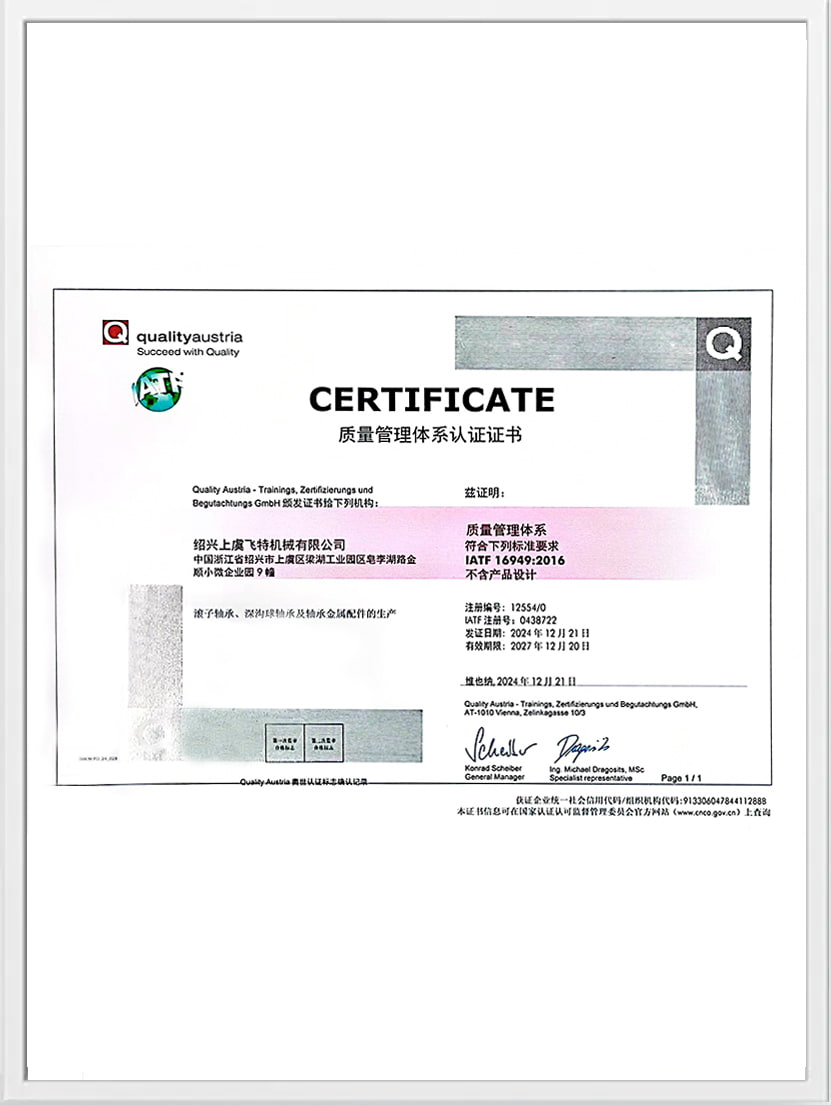

Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM), established in 2006, leverages over 30 years of profound technical design expertise to stand as a premier manufacturer in the R&D, manufacturing, and customization of non-standard bearings, high-precision bearings (import substitution), and related mechanical components. Our commitment to quality has earned us an excellent reputation, enabling our professional technical team to deliver superior bearing solutions across critical sectors, including engineering machinery, textile machinery, and beyond.

Product Focus: High-Performance Vacuum Pump Bushings

Vacuum pump bushings are critical components designed to ensure the smooth, efficient, and reliable operation of various mechanical systems. At FTM, we specialize in customizing these bushings to meet the exacting standards of demanding applications.

Core Function and Application

A bushing acts as an essential intermediary between a shaft and its housing (such as a gearbox). In a vacuum pump or related automotive/mechanical system:

- Protection and Support: It provides stable support for the rotating shaft, preventing direct metal-to-metal contact with the housing.

- Friction and Wear Reduction: By utilizing high-wear-resistant materials, the bushing effectively minimizes friction and wear during dynamic motion, significantly extending the lifespan of both the shaft and the costly housing component.

- System Reliability: A precisely engineered bushing is paramount to improving the overall operating efficiency and reliability of the system, which is crucial in high-speed or high-load environments.

Versatile Application Fields

FTM's customizable bushings are specifically engineered for high-stakes applications, including:

- New Energy Vehicles (NEV): Ensuring smooth operation and longevity in critical subsystems like the automotive gearbox.

- Aerospace: Meeting stringent performance and reliability standards under extreme conditions.

- Construction Machinery: Providing robust support in heavy-duty, high-wear environments.

- General Vacuum Pump Systems: Optimizing performance across various industrial vacuum applications.

Technical Specifications & Customization Capabilities

| Feature |

FTM Customization Advantage |

| Material Options |

Bearing Steel (GCR15), Stainless Steel, other specialized metal alloys tailored for wear resistance and hardness. |

| Size Range |

Fully customized within the 10mm to 250mm range. |

| Design Customization |

Bespoke design of channels, chamfers, and precise geometric features to meet specific lubrication and installation requirements. |

| Surface Finish |

Custom-specified roughness, precision grades, and surface treatments (e.g., specialized coatings) to optimize performance and reduce friction. |

FTM Manufacturer Advantage: Why Choose Us?

As a specialist in non-standard and high-precision components, FTM offers unique advantages:

- 30+ Years of Technical Mastery: We bring deep, proven expertise to the design and analysis of complex dynamic systems, ensuring your bushing is optimized for its specific operating environment (load, speed, temperature).

- Import Substitution Quality: Our high-precision manufacturing capabilities allow us to produce components that meet or exceed the quality and performance of international brands, providing a cost-effective and reliable alternative.

- End-to-End Customization: From material selection to final surface treatment, we offer complete customization, ensuring a perfect fit and function for your unique non-standard equipment requirements.

- Wear Resistance Focus: We rigorously select and process wear-resistant materials to guarantee maximum operational lifespan and minimal maintenance downtime.

- Quality Engineering Solutions: Our service extends beyond manufacturing; we provide professional consultation to deliver high-quality bearing solutions across complex engineering challenges.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lifespan of an FTM vacuum pump bushing?

A: The lifespan is application-dependent, but our material selection (e.g., GCR15) and precision finishing are designed to maximize wear resistance. With proper lubrication and maintenance, our bushings offer a significantly extended service life compared to standard alternatives.

-

Q: Can FTM manufacture bushings for high-temperature/high-speed vacuum pumps?

A: Yes. We specify materials and surface treatments that are thermally stable and highly durable under extreme operating conditions. Please provide us with your system's operating parameters for a specialized material recommendation.

-

Q: What information do you require to begin a custom order?

A: We require detailed specifications including: 1) Outer and Inner Diameter (OD/ID), 2) Length, 3) Material preference, 4) Required precision/roughness, and 5) System application (load, speed, temperature). A technical drawing is highly recommended.

-

Q: How do FTM's custom bushings reduce maintenance costs?

A: By reducing friction and wear on the shaft and housing, our high-precision bushings prevent premature failure of more expensive components, thus decreasing unscheduled downtime and the frequency of component replacement.

-

Q: What is the lead time for a custom-sized, non-standard bushing?

A: Lead times vary based on design complexity and material availability. Standard custom orders typically range from 4-6 weeks after final design approval. We will provide an accurate timeline upon receipt of your full specifications.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog