|

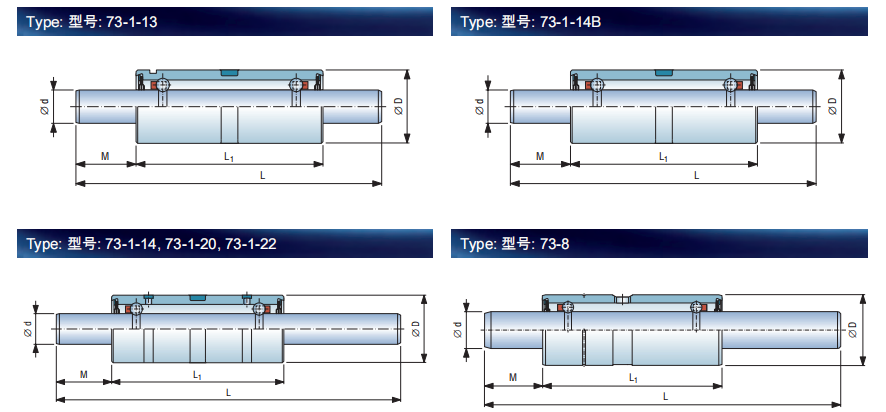

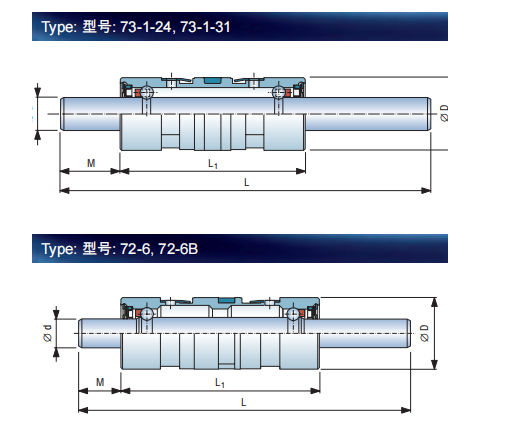

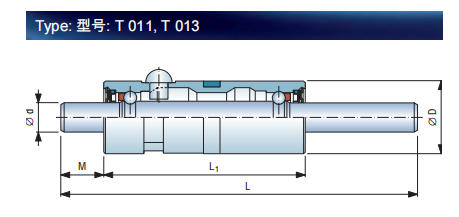

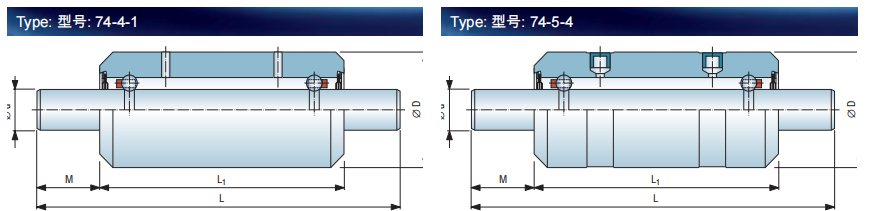

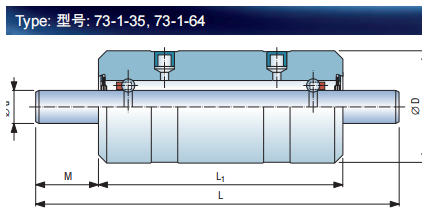

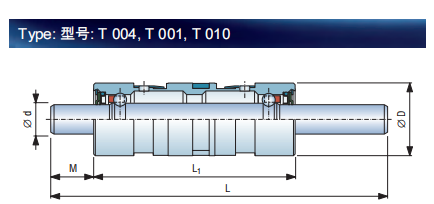

Designation

|

øD

|

ød

|

L

|

Li

|

M

|

Limited

Speed

|

Relubrication

Hole

|

Note

|

|

mm

|

mm.1

|

|

|

|

73-1-13

|

22

|

10

|

92

|

56

|

18

|

40 000

|

No

|

|

|

73-1-14

|

22

|

10

|

112

|

56

|

18

|

60 000

|

Yes

|

|

|

73*1-14B

|

22

|

10

|

112

|

56

|

18

|

60 000

|

No

|

|

|

73-1-20

|

22

|

10

|

112

|

56

|

18

|

40 000

|

Yes

|

|

|

73-1-22

|

22

|

10

|

112

|

56

|

18

|

60 000

|

Yes

|

|

|

73-1-22B

|

22

|

10

|

112

|

56

|

18

|

60 000

|

No

|

*

|

|

73-8

|

22

|

11.5

|

111

|

56

|

18

|

70000

|

Yes

|

*

|

|

73-1-24

|

22

|

10

|

112

|

56

|

18

|

75 000

|

Yes

|

|

|

73-1-31

|

22

|

10

|

112

|

56

|

18

|

80 000

|

Yes

|

|

|

72-6

|

22

|

8.9

|

112

|

61

|

13

|

90 000

|

Yes

|

*

|

|

72-6B

|

22

|

8.9

|

112

|

61

|

13

|

80 000

|

Yes

|

|

|

73-1-35

|

34

|

10

|

110

|

74

|

19

|

15 000

|

Yes

|

|

|

73-1-64

|

34

|

10

|

136

|

74

|

19

|

60 000

|

Yes

|

|

|

74-4-1

|

34

|

12.2

|

112

|

74

|

23.2

|

30 000

|

Yes

|

*

|

|

74-5-4

|

34

|

12

|

110

|

74

|

19

|

30 000

|

Yes

|

Precision Engineering:

Rotor spindles 22-106, are designed for high rotational precision, allowing them to operate at consistent speeds with minimal runout. This precision ensures smooth operation and reduces wear on surrounding components.

High-Speed Operation:

These spindles are capable of running at high rotational speeds, making them suitable for applications where fast rotational movement is critical, such as textile spinning machines or CNC machining centers.

Bearings:

Rotor spindles are equipped with high-precision bearings, such as ball bearings or roller bearings, to minimize friction and wear, ensuring longevity even in high-speed applications.

Dynamic Balance:

Precision rotor spindles require dynamic balancing to prevent vibrations and ensure smooth operation, especially at high speeds. An unbalanced spindle can lead to performance degradation and premature failure of both the spindle and related components.

Cooling and Lubrication:

For high-speed rotor spindles like Type 22-106, efficient cooling and lubrication are crucial. Some systems may include air cooling, liquid cooling, or automatic lubrication systems to maintain optimal performance and extend service life.

Applications

Textile Machinery:

Rotor spindles are commonly used in spinning machines, where they drive rotors that convert fibers into yarn. The high-speed precision of a spindle like the Type 22-106 would be ideal for such an application, ensuring even spinning and high production efficiency.

CNC Machine Tools:

In CNC machining, rotor spindles are used to rotate cutting tools at high speeds with minimal runout. They are essential for accurate material removal, ensuring that parts are machined to tight tolerances.

Manufacturing and Automation:

Rotor spindles are also used in various automation systems that require high-speed rotational motion, such as robotic arms, conveyor systems, and industrial motors.

Precision Instruments:

Applications in measurement devices or lab equipment where high-precision, smooth rotation is critical for data accuracy or sample analysis could benefit from the Type 22-106 spindle's precision.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog