Twin Disc Bearings from Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) are engineered solutions specifically designed to meet the rigorous demands of specialized industrial and textile machinery. These bearings are a cornerstone component, ensuring smooth, stable, and highly efficient rotation between two discs or rollers, often in environments subject to substantial operational stresses. Leveraging FTM's more than 30 years of technical design expertise, our Twin Disc Bearings deliver superior performance and extended service life as a vital part of your critical machinery.

Key Features and Technical Excellence

1. Robust Load Handling Capabilities

- Exceptional Radial Load Capacity: The primary design strength of our Twin Disc Bearings lies in their ability to handle significant radial loads—forces acting perpendicular to the axis of rotation. This makes them indispensable in applications where heavy operational forces are continuously applied.

- Axial Load Adaptability: Depending on the specific design (e.g., the use of tapered rollers or specialized internal geometry), these bearings are also proficient in managing moderate axial loads. This versatility is crucial for applications where slight shifts in the double disc's rotational direction or opposing forces are present.

2. Advanced Design and Construction

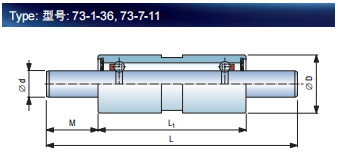

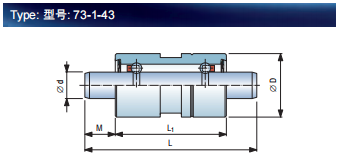

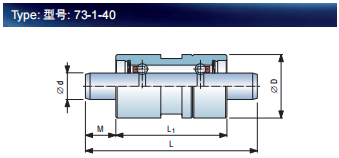

- Double-Row Configuration: Most FTM Twin Disc Bearings utilize a double-row design. This configuration is key to even load distribution across the rolling elements, directly translating to greater load capacity, enhanced rigidity, and superior durability compared to single-row alternatives.

- Rolling Element Variety (Tapered & Cylindrical):

- Tapered Roller Design: Often employed when the bearing must simultaneously accommodate heavy radial and significant axial forces, offering a high degree of rigidity and precision.

- Cylindrical Roller Design: Preferred for applications dominated by pure radial loads and requiring higher speeds, offering excellent shock resistance.

- Self-Aligning Functionality (Where Applicable): For machinery where slight angular misalignment between the shaft and housing might occur—common in large or complex systems—we offer specialized self-aligning Twin Disc Bearings. This critical feature helps compensate for misalignments, prevents edge stresses on the rollers, and maximizes bearing service life.

Why Choose FTM for Twin Disc Bearings?

As a specialist in non-standard and high-precision bearings, FTM offers distinct advantages that ensure our Twin Disc Bearings are an investment in long-term operational reliability:

- 30+ Years of Technical Design Heritage: Our deep-rooted expertise allows us to move beyond standard catalogue products to offer optimal, custom-engineered solutions that address the precise load, speed, and environmental challenges of your machinery.

- Import Substitution Quality: We specialize in the R&D and manufacturing of high-precision bearings that match or exceed the performance specifications of leading international brands, providing you with high-quality, cost-effective alternatives.

- Customization and Adaptability: If a standard twin disc bearing doesn't fit your unique application—whether in textile machinery, heavy equipment, or other industrial machines—FTM excels at full customization. We design bearings for specific dimensions, material requirements, clearance settings, and lubrication needs.

- Application Expertise: Our professional technical team provides comprehensive bearing solutions across diverse fields, including complex textile machinery and high-stress engineering machinery, ensuring you get the right bearing for your job.

FAQ

1. What is the primary advantage of a double-row design in Twin Disc Bearings?

The double-row configuration significantly improves the bearing's load distribution, allowing it to handle much higher radial loads and providing greater rigidity. This translates directly to increased durability and a longer operating life in demanding applications.

2. How do I decide between a Tapered and a Cylindrical Twin Disc Bearing?

You should choose a Tapered design if your application involves significant combined radial and axial loads and requires high precision. Choose a Cylindrical design if the load is predominantly purely radial, and you require higher speed capability and resistance to shock loads.

3. Are FTM Twin Disc Bearings suitable for high-speed textile machinery?

Yes. Our bearings are widely used in textile machinery. We can customize the bearing's internal clearance, cage design, and precision class to ensure minimal vibration, high stability, and reliable performance even at high operating speeds.

4. What does FTM's "Self-Aligning Capability" mean for my machine's lifespan?

Self-aligning capability allows the outer ring of the bearing to adjust slightly to minor shaft deflections or housing misalignments. This prevents the roller elements from carrying concentrated loads (edge stress), which is a major cause of premature bearing failure. Ultimately, it dramatically extends the service life of the bearing.

5. Can FTM manufacture a non-standard Twin Disc Bearing to replace an obsolete part?

Absolutely. Specializing in non-standard bearings is one of FTM's core strengths. We can work with you to analyze the existing specifications, design requirements, and operational environment to reverse-engineer or custom-design a direct replacement with modern materials and precision standards.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog